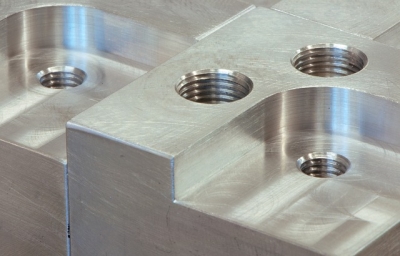

Wisconsin Tool Steel Casting

Tool steel is a high-carbon steel specifically designed for manufacturing tools and dies due to its exceptional hardness, wear resistance and ability to maintain a sharp edge. These steels are alloyed with elements such as chromium, molybdenum and vanadium to enhance their performance under high-stress conditions. Tool steel is commonly used in applications like cutting tools, molds, and industrial machinery, making it essential for various manufacturing processes.

The Perfect Combination of Strength & Agility

Quality Castings beats out competitors with our selection of precision investment alloys. From casting molten material to finished project, our custom-design casting experts carefully handle every stage of formation. No blemish is overlooked.

Browse through our success gallery for our latest casted alloy creations; all completed with excellent quality every time.

Tough-to-Beat Characteristics of Tool Steel Castings

Made from the combination of carbon and alloy steels, tool steel provides everlasting results for every mechanical apparatus. Its true hardness and sustainability gives the material an edge.

Take advantage of the ferrous alloy’s featured properties, such as:

- Tough enough to shape other materials

- Resists deformation & abrasion

- Holds its structure against high temperature treatment

- Extremely hard surface: no chipping, breaking, etc.

- Resists carbon reduction

- Great wear-and-tear strength

Industrial Applications for Tooling Needs

Tool steel plays a significant role in several major industries; all depending on the toughness and stability of the material. Consider choosing tool steel for your next big or small component project.

Applications include:

Plastic molding – production of plastic parts by injecting plastic into a mold cavity

Knife production – manufacturing different grades of knife blades based on cutting strength

Metal punching – stamping metal to produce different shapes for components

Vinyl extrusion – the manufacturing of vinyl for trim, windows, doors, etc.

The Quality Casting Advantage

Tool steel is one of the better choices for needed durability and hardness. Its main property handles heat, tampering, and movement extremely well; great for working with other materials. It’s also inexpensive, which is another major benefit.

Quality Castings crafts the finest components for any project, big or small. Other than tool steel, we also offer ductile iron, carbon steel, and a variety of stainless steels. Look to us for manufacturing machine parts, finishing/polishing, CNC machining, and other metalwork services. Our name says it all.